|

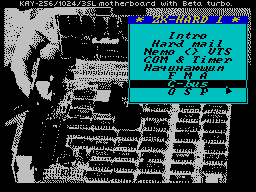

ZX Hard #00

31 августа 1998 |

|

Iron - a beginner: Lessons from soldering.

Iron - for beginners.

(C) ZxNews08/SPb

Tips Wizard

Igor Majorov, 1996

Pechatatayut a lot in magazines completions for SPECCY, well,

there all sorts of schemes, for example, but very few can, it

can make them myself.

And it all is that many do not know how

most important - the soldering.

Today I popobuyu teach you this, if the desire is ...

Take a simple soldering iron in hand. To start prepare him for

work: Sting (the tip of a soldering iron) should be silver. If

not, then we take Needle file and neatly trimmed it.

Then take the file and attach sting

form: a "paddle" if it is necessary to solder

two wires, or "needle" or "cone" for

work with the board, for example.

Now includes a soldering iron to the network, waiting

until it warms up, and consistently

touch tip (dip sting) first

to rosin, and then to tin, and so

to its tin evenly coated.

After this, wipe the tip of a piece of paralon. Everything.

Soldering iron ready to use.

The next stage - the right rations.

Usually, beginners after the first solder

get something, sealed PIECES

tin. Do not be afraid, if you get

so the same result. Skill comes with

experience ...

For a start try to solder together

two "stranded" wire, of which bulk

in any home.

For a good soldering the wires initially cleared somewhere in

the 5 mm in length. For this most often used sharpened

type of surgical cutting tool

scalpel, knife, wire cutters, or at least

Finally, sharp scissors ... Carefully, trying not to cut your

fingers, remove the insulation from the wire. Nothing, if the

first time, instead remove the insulation,

you will cut the wire completely. Several

attempts, and you must succeed.

After removing the insulation, "Scratch" on a bare

parts, such as a knife. Part must

more shine.

Thus, wire tipped. Now it should be

"Zaludit" or "obludit" - and so and so

say.

Take the bare wire and a hot soldering iron not for long press

it into rosin, and then removed.

After that, melt a small piece of soldering tin, again touch

to skim through the end of rosin

wire and a little scroll it around

its axis so that the tin evenly coated bare plot.

Perform the same operation with the second wire.

Then, imposing the "tinned" wire to each

on the other, touching them with hot soldering iron, dip it in

Rosin.

Everything. Now allot a soldering iron and give the wire to

cool, in any case is not blowing at them (this affects the

quality of soldering).

That's all business!

To learn how to work with the board, we

talk to you next time.

__________________________

(C) ZxNews09/SPb

Other articles:

Similar articles:

В этот день... 23 February