|

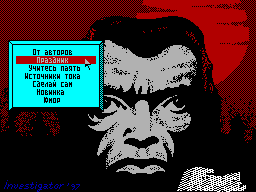

Aspect #01

05 декабря 1997 |

|

Learn how to solder - techie rations for Dummies.

(C) Igor Majorov, 1996

(R) Sergey Romanov and Fedy Savin, 1997

Take a simple soldering iron in hand. To start prepare him for

work: Sting (the the tip of a soldering iron) should be silver

color. If not, then we take the Needle file

or file, and it neatly trimmed.

Then, take the file and attach

sting shape of a "shoulder" if

need to solder two wires, or

"Needle" or "cone" to work with

board, for example. (See fig.)

Now includes a soldering iron to the network,

Wait until it warms up, and consistently

touch tip (dip sting) first to the

rosin, and then to tin, and so

to its tin evenly coated. After

Wipe the tip on this piece of cloth.

Everything. Soldering iron ready to use.

The next stage - the right rations.

Usually, beginners after the first solder

get something, sealed tin PIECES. Do not be afraid, if you get

the same result. Skill comes with experience ... For a start

try to solder together two "stranded" wire, of which bulk in

any home.

For a good soldering the wires initially cleared somewhere in

the 5 mm in length. To do this more often often used sharpened

cutting tool such as a surgical scalpel,

knife, pliers, or, at worst, a sharp

scissors ... Carefully, trying not to cut

fingers, remove the insulation from the wire. Nothing, if the

first time, instead of remove the insulation, you will cut the

wire completely. Several attempts, and you must succeed. After

removing the insulation, Scratch on bare parts, such as a

knife. Part should shine stronger.

Thus, wire tipped. Now it should be "zaludit" or "obludit" -

and so, and say so. Take the bare wire, and a hot soldering

iron not for long press it into rosin and then removed.

After that, melt a small piece of soldering tin, once again

touch the skim through the end of rosin

wire, and a little scroll it around

its axis so that the tin evenly

covered the exposed area. The same operation

place from the second wire.

Then, imposing the "tinned" wire to each

on the other, touching them with hot soldering iron, dip it in

resin. Everything. Now allot a soldering iron and give the wire

to cool, in any case is not blowing on them - It affects the

quality of rations. A few words about how to solder

mozhdu a neslolko wires:

Right-spike wires.

"Do not correct the spike wires.

Now let's talk about how to deal with

pechatnoy board and its components.

The printed circuit board consists of a sheet

foil getinaksa or PCB,

on which are etched conductive paths.

The board has openings (holes), where

will then be soldered circuit elements, well, then

there are all sorts of details.

Typically, these openings have obluzheny so

that no problems arise. But if

got "left" card, then before the assembly

printed conductors and contact pads

need to prepare for soldering - clear

from the oxide film and contamination.

If the date of manufacture boards gone

a lot of time and a metal coating darkened (oxidized), it must

first clean up its fine to shine sandpaper, and then -

thoroughly rinse with alcohol (not required). After degreasing,

all pads board brush applied a thin layer of rosin flux.

(Composition,%: Rosin - 15-18, the rest

alcohol; Rosin - 6, Glycerin - 14, alcohol

Ethyl - everything else). Well, if you

did not have any items from the flux

rastraivaytes do not, you can simply take

the tip of a soldering iron a little tin, and then

its a bit pressed into rosin and quickly

(Not yet vaporized rosin) touch

sting to the place which must zaludit, and wait a little longer

remove it. That place zaluditsya. If you have flooded the hole

with tin you have a bigger impact esgo too mnego took the sting.

For the latter method requires a good

training.

Radioelements and chips also need to prepare for assembly and

soldering. For of their findings (leg) form (attached

them the desired shape), cut to

length, if necessary, sanded and ludyat.

Forming can be done with tweezers, mini pliers or other

similar instruments / devices.

Since the adhesion foil

Pay is low and decreases when heated, then try to keep the

soldering iron does not warming cost more than 5 seconds.

Soldering boards should apply solder

low melting point: POSCO 50,

PIC 61 and other power soldering iron - no more

35-40 Tues Soldering iron should have needle-like sting

(although this is at your discretion) ostrozatochennoe and

obluzhennoe.

Soldering of circuit elements is performed as well as

soldering 2 obluzhennyh wires, ie insert details in the right

leg openings and heat them alternately.

Other articles:

Similar articles:

В этот день... 13 February